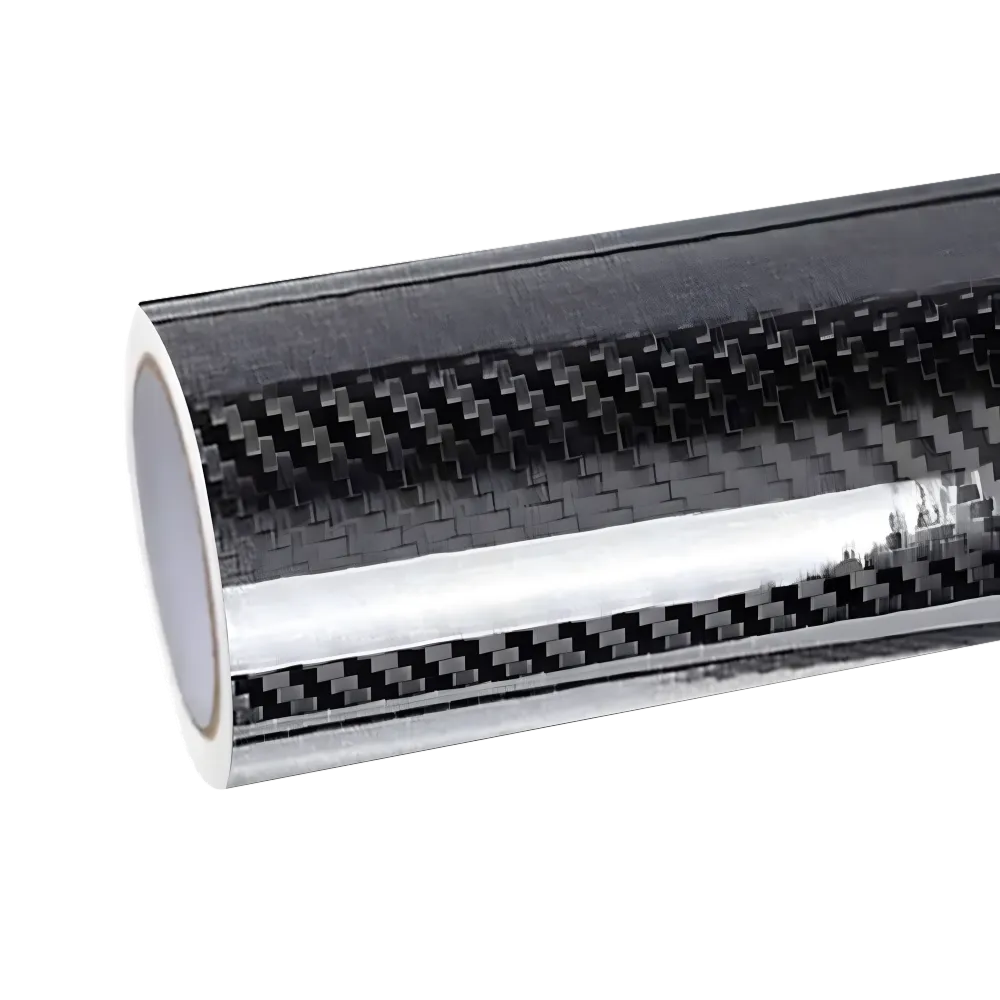

Want the motorsport look without sacrificing paint safety? Carbon fiber paint-protection film (PPF) pairs a realistic weave aesthetic with the durability of aliphatic TPU—bringing rock-chip resistance, heat-activated self-healing, UV stability, and a slick, hydrophobic finish to high-end builds.

What Carbon Fiber PPF Is—And How It Differs from Regular Wraps

Carbon fiber PPF is a textured, protective film engineered from aliphatic TPU (thermoplastic polyurethane) with a carbon-weave visual layer and a self-healing, clearcoat-like topcoat. Unlike a cosmetic vinyl wrap that changes color but offers limited impact resistance, a dedicated ppf wrap is designed first for protection—absorbing road rash, minor abrasions, and debris strikes while preserving OEM paint.

For buyers who love the motorsport vibe on hoods, roofs, mirrors, or lower valances—but won’t compromise on paint safety—carbon fiber PPF is a sweet spot. You get the look, plus self-healing and chemical resistance that standard vinyls typically lack.

How It Protects: Thickness, Self-Healing & Hydrophobics

Protection thickness you can measure

Premium PPFs used on luxury vehicles commonly land in the 8–10 mil range (≈203–254 µm). This thickness has become an industry sweet spot that balances robust chip resistance with conformability over complex curvature. Authoritative installer guides and manufacturers consistently recommend ~8 mil for mainstream protection and up to ~10–12 mil for harsher conditions.

Heat-activated self-healing that resets micro-marring

The self-healing layer on aliphatic TPU softens and flows when warmed (sun, warm water, or a heat gun), allowing light swirls to relax and “close.” Practical explanations peg the useful activation window around the polymer’s glass-transition behavior—often near ~40 °C / 104 °F for modern PPF topcoats.

Hydrophobic topcoats for easier washing

Carbon fiber PPFs usually add a slick, hydrophobic layer with water contact angles measured near ~105°. This reduces water spotting and makes routine maintenance faster, especially on darker finishes that show dust.

Why Luxury Owners Choose Carbon Fiber PPF

UV stability & clarity

Aliphatic TPU is favored for optical clarity and non-yellowing under UV, a key requirement for high-end vehicles and carbon-pattern films that must stay crisp over time.

7–10 year longevity

With professional installation and proper care, modern aliphatic TPU PPFs commonly last 7–10 years on the vehicle—supported by multiple brands’ lifecycle data.

Authentic motorsport look

Carbon fiber PPF provides a convincing weave in gloss or matte that reads premium up close yet remains protective like a clear bra. Aluko’s carbon fiber ppf is a good example of this dual role.

Key Specs & Comparison

| Property | Carbon Fiber PPF (aliphatic TPU) | Standard Color Vinyl Wrap |

|---|---|---|

| Typical thickness | ~8–10 mil (203–254 µm) | ~3–4 mil (≈75–100 µm) |

| Impact & chip resistance | High—purpose-built for road debris | Low–moderate—primarily cosmetic |

| Self-healing clearcoat | Yes; heat-activated (~40 °C) | No |

| Hydrophobicity | Common; contact angle ≈ 100–105° | Varies; often requires ceramic top-coat |

| UV stability (yellowing) | Excellent with aliphatic TPU | Varies by PVC/PU chemistry |

| Aesthetics | Realistic carbon weave (gloss or matte) | Unlimited colors/finishes |

| Primary use case | Protection first, style second | Style first, light protection |

Measurements and behaviors above reflect widely documented industry guidance on PPF thickness, self-healing behavior, hydrophobic contact angles, and aliphatic TPU UV stability.

Choosing Gloss vs. Matte Carbon Finishes

Gloss carbon PPF mimics clear-coated carbon parts with depth and pop—ideal for black, gray, and jewel-tone paints. Matte carbon PPF subdues glare and pairs well with stealth builds. Both preserve paint while adding weave texture. For an on-site example of gloss patterning, see Aluko’s dedicated carbon fiber ppf product page.

Care, Cleaning & Warranty Expectations

Maintenance rhythm

- Wash weekly or bi-weekly with pH-neutral soap; avoid harsh solvents.

- Dry with plush microfiber to reduce spotting (hydrophobic films sheet water quickly).

- Decontam quarterly with gentle iron removers safe for PPF.

- Top-up protection with PPF-safe sealants if desired; many films already integrate a durable topcoat.

Service life

Expect 7–10 years from quality aliphatic TPU PPF under typical use, with climate and maintenance affecting the upper range.

Installation Best Practices for a Flawless Carbon Look

- Panel selection: Carbon weave looks exceptional on hoods, roofs, mirror caps, rocker panels, and splitters—high-impact zones that also benefit most from PPF’s chip resistance.

- Surface prep: Clay, degrease, and panel-wipe to maximize adhesion and clarity. (Professional shops often reference ASTM/industry test methods to validate clarity and abrasion resistance of topcoats.)

- Conform & align: Because the weave is directional, align patterns symmetrically across panels before final tack-down.

- Edge strategy: Where feasible, wrap-in edges for an OEM-like finish; use relief cuts sparingly.

- Heat-set & post-check: Warm gently to activate initial self-healing and ensure full bond, then re-inspect after 24–48 hours for micro-bubbles that often dissipate.

If you’re also considering full color changes, explore Aluko’s performance TPU range for colored ppf, or browse the brand’s complete PPF lineup here: ppf wrap. For purely cosmetic finishes, a traditional vinyl wrap remains an option—but for high-impact areas, the protective layer of PPF is hard to beat.

Quick FAQ

Will carbon fiber PPF yellow over time?

High-grade aliphatic TPU is engineered for UV stability and colorfastness, resisting the yellowing that can occur with aromatic TPU chemistries.

Does the weave look “real” up close?

Yes—modern films use a convincing pattern layer below the self-healing topcoat, available in gloss or matte to match the design language of true carbon parts.

How long does protection last?

With professional installation and sensible care, expect a service window of about 7–10 years before replacement, varying by climate and wash routine.

What’s the ideal thickness?

For luxury daily drivers, 8–10 mil strikes an excellent balance between chip resistance and conformability; heavy track or off-road use may justify thicker films.

References (Selected)

- PPF thickness norms and recommendations (8–10 mil).

- Self-healing behavior and heat activation near ~40 °C / 104 °F.

- Hydrophobic contact angles ≈ 100–105°.

- Aliphatic TPU UV stability vs. aromatic TPU.

- PPF longevity (7–10 years) under proper care.

- Product example—gloss carbon weave PPF.