Colored paint protection film (PPF) has moved from niche “show car” status to a serious alternative to repainting and traditional vinyl wraps. Today’s color PPF combines a color-change effect with the same impact resistance, self-healing and UV protection that clear PPF is known for, giving installers a higher-value upgrade to offer detail and styling clients.

1. What Is Colored Paint Protection Film?

Colored paint protection film is built on the same architecture as traditional clear PPF: a pressure-sensitive adhesive, a thermoplastic polyurethane (TPU) core layer, and a protective topcoat.:contentReference[oaicite:1]{index=1} Pigments, metallic flakes, or effect particles are integrated into the film so you can change the vehicle’s color without sacrificing the chip resistance and self-healing performance that modern PPF offers.

Compared with older PVC or TPH films, aliphatic TPU-based PPF stays clearer, resists yellowing longer, and works better with flexible self-healing clear coats.:contentReference[oaicite:3]{index=3} When heat or warm water is applied, the topcoat can relax minor swirls so the surface visually “repairs” itself. This combination of TPU and advanced topcoat chemistry is what lets colored PPF deliver both a custom look and OEM-grade protection on the same panel.

2. Colored PPF vs Clear PPF vs Traditional Car Wrap

For many owners, the first decision is whether to run a conventional car wrap, a transparent film, or a full colored paint protection film. Traditional vinyl wraps are mostly cosmetic, usually thinner than PPF and easier to mark with rock chips and deep scratches. Colored PPF, by contrast, is built to take more impact abuse while still offering a gloss, satin, or textured appearance that looks “paint-like” rather than like a sticker.

Clear PPF remains the go-to choice for clients who love their OEM color and simply want an invisible shield. Alukovinyl’s clear ppf range is a good example: a high-clarity urethane film designed to keep factory paint intact while absorbing chips, UV and etching. Colored paint protection film enters the picture when customers want both a color change and protection in one layer—essentially a “color-change PPF” that behaves like a ppf wrap rather than a standard vinyl.

3. Top Colored Paint Protection Film Brands and Systems

The global PPF market is dominated by a small group of manufacturers whose films are widely installed by high-end detailers and wrap shops. Industry comparisons regularly list Aluko alongside XPEL, 3M (Scotchgard), SunTek/LLumar, STEK, and Ceramic Pro KAVACA among the leading options for gloss, clarity, self-healing, and warranty coverage. Many of these brands now offer colored or effect-PPF lines in addition to standard clear film.

Outside the OEM-style brands, specialist manufacturers focus almost entirely on colored paint protection film. Examples include metallic and color-shift paint protection lines from TeckWrap and dedicated colored PPF systems like VVIVID’s ColorFusion and PURE PPF’s matte and metallic series, which embed color deep into TPU for longer-lasting vibrancy.These products show how quickly color PPF has evolved: rather than simply tinting a clear bra, manufacturers are engineering full palettes—solid, metallic, pastel, pearl and chameleon—in protective film form.

On Alukovinyl’s side, the ALUKO line offers a broad catalog of colored PPF options, including gloss, satin, ultra-matte, metallic and carbon-fiber textured variants. The color ppf category alone spans hundreds of SKUs covering OEM-inspired shades like Nardo Grey, Porsche Oak Green and Ferrari Red, as well as trend colors such as Tiffany Blue and desert tones.For installers, this breadth means you can keep protection performance consistent while tailoring color and finish to each customer’s build.

4. Popular Finishes in Colored Paint Protection Film

4.1 Gloss and Ultra-Gloss

Gloss colored PPF aims to mimic fresh paint: high DOI (distinction of image), strong reflectivity and smooth, low “orange peel.” Ultra-gloss or “wet look” formats amplify this effect for show-car or luxury builds, especially when paired with deep solid colors or metallic flake. High-gloss TPU films from leading manufacturers showcase how self-healing topcoats can maintain that wet look while resisting micro-marring and contaminants over the long term.

4.2 Matte and Satin Stealth

Matte and satin colored PPF give clients the “stealth” look that’s popular on performance and premium SUVs. Products like XPEL STEALTH show how a satin top layer can dramatically change the character of a car while still functioning as a full protective barrier. Alukovinyl’s own matte and satin paint protection films blend this low-gloss aesthetic with the same chip and UV resistance as traditional PPF, making them ideal for customers who want to tone down reflections without repainting.

4.3 Metallic, Pearl, Color-Shift and Textures

Metallic and pearlescent colored paint protection film integrates reflective flakes or pearl pigments directly into the TPU, achieving effects that previously required multi-stage paint. Color-shift, “flip” or chameleon films push this further, changing hue with viewing angle or lighting and giving wrap shops a high-impact look that still behaves like a true protective film.

Textured colored PPF—such as carbon-fiber patterns—adds a tactile dimension while maintaining hydrophobic and self-healing properties. Alukovinyl’s carbon-fiber PPF, for example, uses a TPU construction with UV-resistant coatings to avoid yellowing and orange peel while providing a 3D pattern.For clients who want both a motorsport-inspired texture and long-term protection, textured colored PPF is a strong upgrade over printed vinyl.

5. Key Technical Specs to Compare

When you compare colored paint protection film for your shop, start with the base polymer and thickness. Modern high-end PPF uses aliphatic TPU as the core layer because it delivers superior clarity, flexibility and resistance to yellowing compared with older PVC or TPH materials.Typical thickness ranges from about 7–10 mil, with thicker films often used on high-impact or off-road applications.

The topcoat is equally critical. Advanced clear coats can be hydrophobic, stain-resistant and heat-activated self-healing, allowing light scratches to recover when exposed to warmth or hot water. This layer also influences how the surface feels (slick vs “grabby”) and how easy it is to maintain; a good topcoat should shed dirt and traffic film instead of holding onto it.

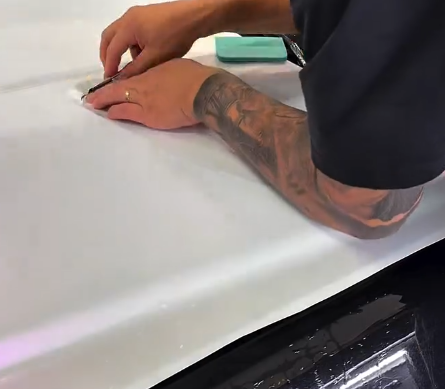

Adhesive technology and install method also affect shop efficiency. Many modern colored PPF lines use low-tack, wet-applied adhesive systems that allow repositioning during installation and limit lift lines on complex panels.Look for consistent release liners, good slide characteristics with slip solution, and compatible edge-sealing recommendations so you can deliver clean installs that stay put for the lifetime of the film.

6. Application Considerations for Installers and Shops

Colored paint protection film changes how you plan coverage. Full-body colored PPF is ideal for clients who want to completely transform their vehicle while locking in OEM paint underneath; partial front-end coverage with colored film is less common because color breaks are more visible than on clear products. Many shops will combine a full colored PPF wrap with clear PPF on high-impact areas that need extra, easily replaceable layers.

Color selection also carries more weight than with clear films. Because colored PPF overlays the existing finish, installers should discuss how the base color might subtly influence the final shade, especially with lighter or semi-translucent films. Tools such as color-chip decks, display hoods, or demo panels wrapped in different colored PPF help set realistic expectations before committing an entire roll to one vehicle.

Finally, installation environment and aftercare are non-negotiable. Colored PPF reveals stretch marks and contamination more obviously than clear films, so shops should maintain clean, climate-controlled bays and respect curing windows before washing or handing vehicles back to clients. Following manufacturer-recommended soaps, pH-neutral cleaners and maintenance products ensures that hydrophobic and self-healing properties remain effective for years, not just months.

7. How Alukovinyl Fits Into the Colored PPF Landscape

As demand for colored paint protection film increases, many installers are looking for suppliers that can provide both broad color coverage and dependable TPU construction. Alukovinyl’s portfolio spans clear, matte and colored PPF options, with ALUKO-branded films designed to compete directly with global leaders on clarity, self-healing, and hydrophobic performance while offering a deep catalog of designer colors. This makes it easier for shops to standardize on one ecosystem for both mainstream clear PPF jobs and high-margin color-change projects.

For installers and distributors, the take-away is simple: colored paint protection film is no longer a fringe upgrade. With the right mix of film quality, finish options, and installation best practices, colored PPF lets you offer clients a custom aesthetic, preserve OEM paint, and build a higher-value service line than traditional wrapping alone.